Wood Inserts

Thompson's Hearth & Home in Issaquah brings you the unmatched charm of a wood stove—no other home feature rivals the authentic, mesmerizing glow and comforting warmth of a real wood-burning fire.

We proudly feature premium wood stove inserts from some of the world's finest manufacturers:

Hearthstone (crafted in Vermont, USA) — Renowned for innovative TruHybrid™ technology that combines non-catalytic re-burn with hybrid elements for ultra-clean performance.

Jøtul — A legendary Norwegian company founded in 1853 and famous for producing some of the finest cast iron in the world. High-quality cast iron components are sourced from Norway and shipped to their North American facility in Gorham, Maine (near Portland), where stoves and inserts for the U.S. are manufactured.

Rais and Morsø (both from Denmark) — Offering distinctive Scandinavian design, timeless beauty, exceptional heat output, and top-tier efficiency.

All our wood inserts are EPA-certified under the 2020 New Source Performance Standards (NSPS), meeting or exceeding the strict particulate emissions limit of 2.0 g/hr. Many achieve even lower levels—for example:

Hearthstone models often test as low as 0.54 g/hr (e.g., Heritage series) or 1.14 g/hr, with efficiencies up to 80–81% HHV.

Morsø inserts like the 5660 series are certified around 1.55 g/hr and carry the Nordic Swan Eco-label for low emissions and sustainable production.

Rais models (such as Q-Tee II inserts) are recognized for clean non-catalytic burns that comply fully with EPA rules.

This certification highlights their efficient use of wood as a renewable resource, ultra-low emissions for better air quality, and compliance with regulations—even during burn bans in the Puget Sound region.

Why Choose a Wood Insert?

Wood inserts are a smart, popular upgrade for existing masonry fireplaces. Many are precisely engineered to fit right into your current fireplace opening, turning a drafty, inefficient hearth into a powerful whole-home heat source. This can substantially cut heating costs by providing reliable, warmth throughout your home—perfect for Northwest winters.

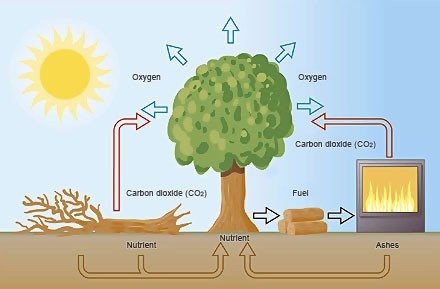

Natures Cycle

Wood has a truly remarkable relationship with CO₂ in the context of the natural carbon cycle, making it a potentially sustainable heating fuel when managed responsibly—especially for home use like in wood stoves or inserts.

The Basic Carbon Cycle for Wood

During growth, trees absorb carbon dioxide (CO₂) from the atmosphere through photosynthesis, converting it into oxygen (released back into the air) and storing carbon in their trunks, branches, roots, and leaves as part of building woody biomass.

When a tree dies and decomposes naturally (or is burned efficiently), that stored carbon is released back into the atmosphere as CO₂—roughly the same amount that was absorbed during its lifetime.

This creates a closed, short-term cycle (decades to a century, depending on tree species and forest management), unlike fossil fuels (oil, coal, gas), which release ancient, long-sequestered carbon that has been out of the active cycle for millions of years, adding net new CO₂ to the atmosphere.

If burning is efficient (complete combustion in a modern, EPA-certified stove) and forests are sustainably managed—meaning new trees are planted or naturally regenerate to replace harvested ones—the process can be CO₂-neutral over time. No additional carbon is permanently added to the atmosphere; it's simply recycled within the biosphere. This is why wood is often classified as a renewable, green energy source for heating, particularly at the residential scale where local, sustainably sourced firewood is used.

Key Advantages Over Fossil Fuels

Renewability: Wood can be replenished by planting or allowing new growth—maintaining the neutral cycle generation after generation—as long as harvest rates don't exceed forest regrowth.

Local and low-impact sourcing: In the Northwest (like Washington state), using firewood from managed forests, thinning, or storm-fallen trees keeps transport emissions minimal and supports healthy forest ecosystems.

Efficiency in modern appliances: EPA-certified stoves burn cleaner, with very low particulate emissions (2.0–2.5 g/hr or less), maximizing heat output while minimizing waste and air pollution.

In summary, for homeowners using efficient, EPA-certified wood stoves with responsibly sourced firewood, burning wood can indeed be a CO₂-neutral (or very low-net-carbon) way to heat your home—recycling carbon that's already part of the active cycle while avoiding fossil fuel emissions. It's one of the few truly renewable home-heating options available, especially as a backup during power outages in the Northwest.

Catalytic vs Non Catalytic

The 1970s energy crisis sparked a massive increase in wood stove and insert use as people sought affordable, renewable alternatives to rising oil and gas prices. This boom exposed the high pollution from older, inefficient appliances, which often emitted up to 100 grams per hour (g/hr) of particulate matter (fine smoke particles that harm air quality and health).

To address this, the U.S. Environmental Protection Agency (EPA) established the first New Source Performance Standards (NSPS) for residential wood heaters in 1988 (commonly referenced around 1990). These set particulate emissions limits of:

7.5 g/hr for non-catalytic wood stoves (national standard).

4.1 g/hr for catalytic models (with Washington State adopting a stricter 4.5 g/hr limit in the mid-1990s, influencing broader trends).

This regulatory push drove innovation, birthing the modern wood stove era with cleaner technologies.

Catalytic combustors emerged as an early, effective way to meet these standards. By chemically igniting smoke at lower temperatures (~500°F vs. 1,000°F+ required otherwise), they reduced emissions significantly—especially during startup and low burns. However, they came with challenges:

Required manual bypass dampers during startup and reloads to prevent the catalyst from getting coated or plugged by cool smoke.

Fragile construction (honeycomb ceramic or metal substrate coated with precious metals like platinum/palladium), prone to physical damage, peeling, plugging, or loss of catalytic activity.

Degradation over time: As highlighted in the 1998 EPA-commissioned Residential Wood Combustion Technology Review by OMNI Environmental Services (the excerpts you referenced are accurate to that report), emissions from many catalytic stoves increased under normal use—sometimes reaching levels similar to older uncertified stoves (up to ~100 g/hr) within 5 years or faster with heavy/high-temperature operation.

Due to these reliability, maintenance, and user-operation issues (plus costly replacements), many manufacturers transitioned to non-catalytic re-burn systems (using secondary combustion tubes, baffles, high-velocity air, and optimized high temperatures for consistent clean burns without extra fragile parts).

In 2015, the EPA finalized updated NSPS with a phased approach:

Step 1 (effective ~2015): Uniform 4.5 g/hr limit for all new wood stoves.

Step 2 (effective May 15, 2020): Stricter 2.0 g/hr weighted average (crib-wood test method) or 2.5 g/hr (optional cordwood test method, more representative of real firewood).

No major changes have occurred since 2020—the current standards remain in place as of 2026. The EPA is conducting a required review (under Section 610 of the Clean Air Act) of the NSPS for residential wood heaters, with a deadline to complete by December 15, 2026, but no new limits have been proposed or implemented yet.

These rules represent a huge leap—reducing emissions by ~75–98% compared to pre-1988 uncertified stoves—and apply only to newly manufactured/sold units (existing stoves remain legal to own/use). Modern non-catalytic (or hybrid) designs from brands like IronStrike, Rais, and Morsø routinely meet or exceed these limits with durable, low-maintenance re-burn tech, delivering reliable performance without catalytic drawbacks.